FOR ROCKY MOUNTAIN OPERATORS

Maximize Production Across Your Rocky Mountain Assets

Iron-IQ delivers proven production uplift for operators across Colorado, Wyoming, and New Mexico through continuous lift cycle visibility and cloud-native SCADA built specifically for Rocky Mountain gas operations.

REGIONAL EXPERTISE

Built for Rocky Mountain Basins

Iron-IQ understands the unique operational and regulatory challenges across the Rocky Mountain region. From the DJ Basin to the San Juan, our platform delivers proven results where it matters most.

COLORADO

DJ Basin & Front Range

High-density operations across Weld, Adams, and surrounding counties. Stricter regulatory environment with COGCC oversight.

Stripper & marginal well optimization

COGCC compliance & reporting

Urban interface operations

Scattered asset management

WYOMING

Powder River & Green River

Large-scale operations across vast acreage. Remote locations demand reliable remote monitoring and minimal field visits.

Remote asset monitoring

Large acreage coverage

CBM & conventional gas

Extreme weather resilience

NEW MEXICO

San Juan Basin

Mature fields requiring enhanced recovery and optimization. Mix of conventional and unconventional production.

Mature field optimization

Enhanced recovery operations

Multi-basin coordination

State regulatory compliance

OPERATOR CHALLENGES

The Reality of Operating in the Rockies

Rocky Mountain operators face unique challenges that traditional SCADA systems weren't built to solve.

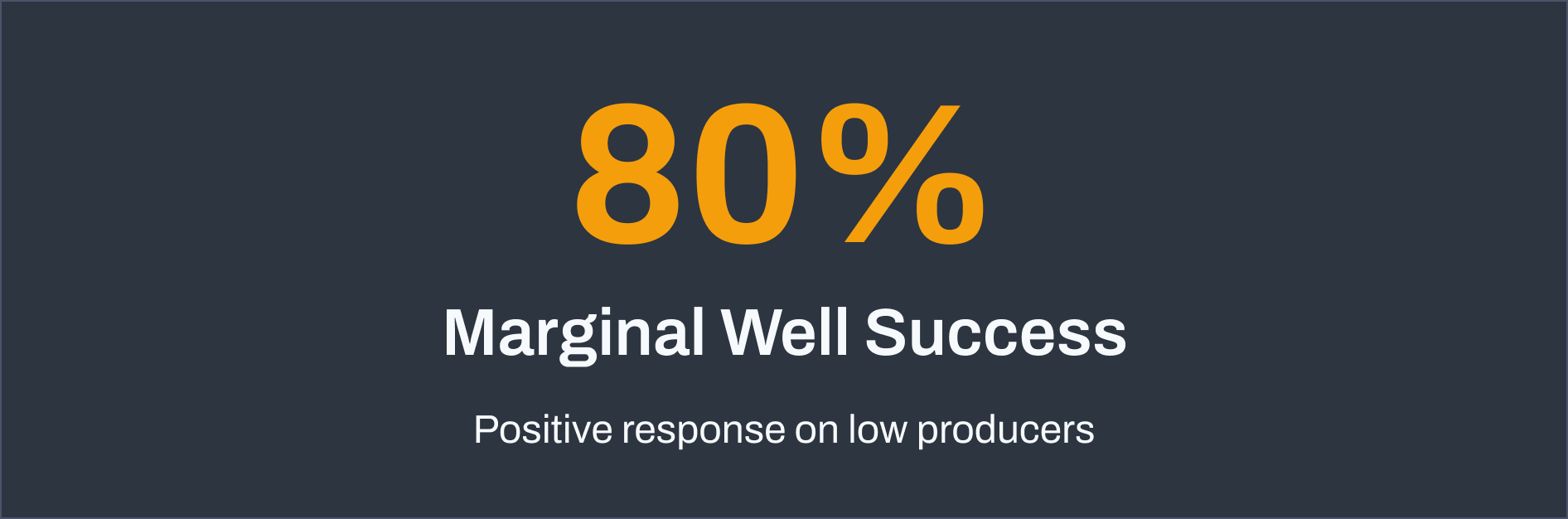

Stripper & Marginal Wells

Low-producing wells with 0-25 mcf/day need every optimization opportunity to remain economic, but polling-based SCADA misses the details that drive uplift.

Geographic Dispersion

Wells spread across multiple basins and states require expensive field visits. You need to know which wells actually need attention before sending trucks.

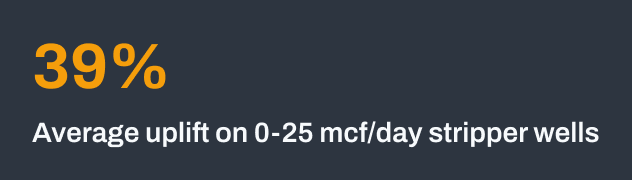

Thin Margins & Economics

Every dollar counts when margins are tight. Traditional SCADA's high infrastructure costs and ongoing IT overhead eat into already slim returns.

Acquisition Integration

Acquiring assets across multiple basins means integrating different control systems, data formats, and operational practices quickly and cost-effectively.

Multi-State Compliance

Different regulatory requirements across Colorado (COGCC), Wyoming (WOGCC), and New Mexico (OCD) demand flexible compliance and reporting capabilities.

Remote Operations

Wells in remote Wyoming or New Mexico locations can't rely on frequent field visits. Need reliable remote monitoring and control capabilities.

BUILT FOR ROCKY MOUNTAIN OPERATIONS

How Iron-IQ Solves These Challenges

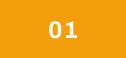

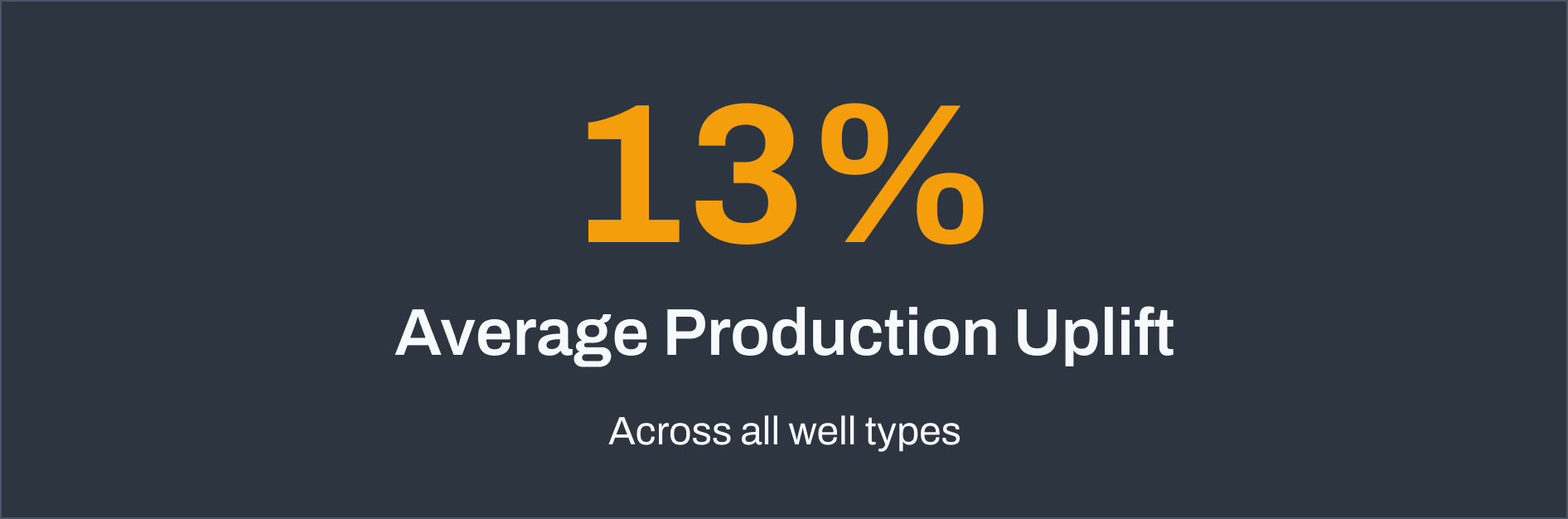

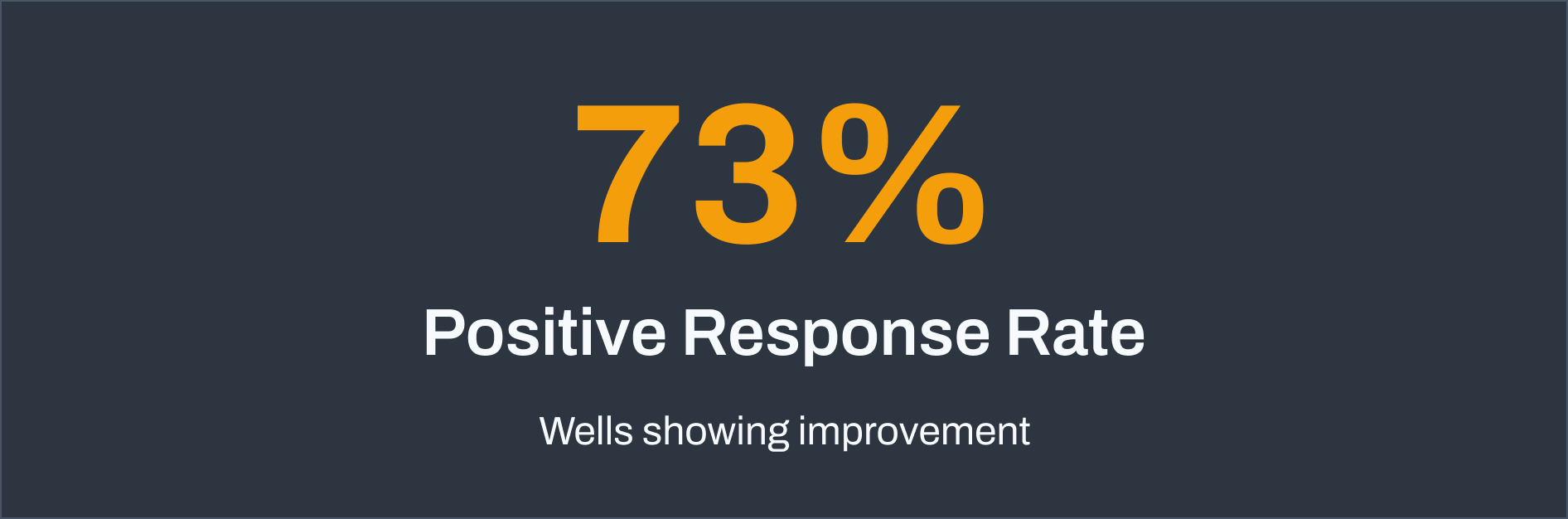

Maximize Marginal Well Economics

Complete lift cycle visibility identifies optimization opportunities that polling misses. Our Rocky Mountain cohort proves the value.

Reduce Field Visit Costs

Know exactly which wells need attention before you send a truck. Cloud-native dashboards accessible from anywhere in the region.

Multi-State Compliance

Automatic audit trails, complete data history, and configurable reporting that meets regulatory requirements across CO, WY, and NM.

Cost Structure That Scales

No hardware replacements. No Windows licensing. No on-prem servers. Pay only for what you use as your operations grow across states.

PROVEN RESULTS

Field-Validated Performance from 90-Well Rocky Mountain Cohort

With these economics, the pricing alone made the decision easy. Once we moved forward, we realized we were getting more capability than we had with our previous provider.

Production Operations Lead

Independent Producer | ~950 Wells

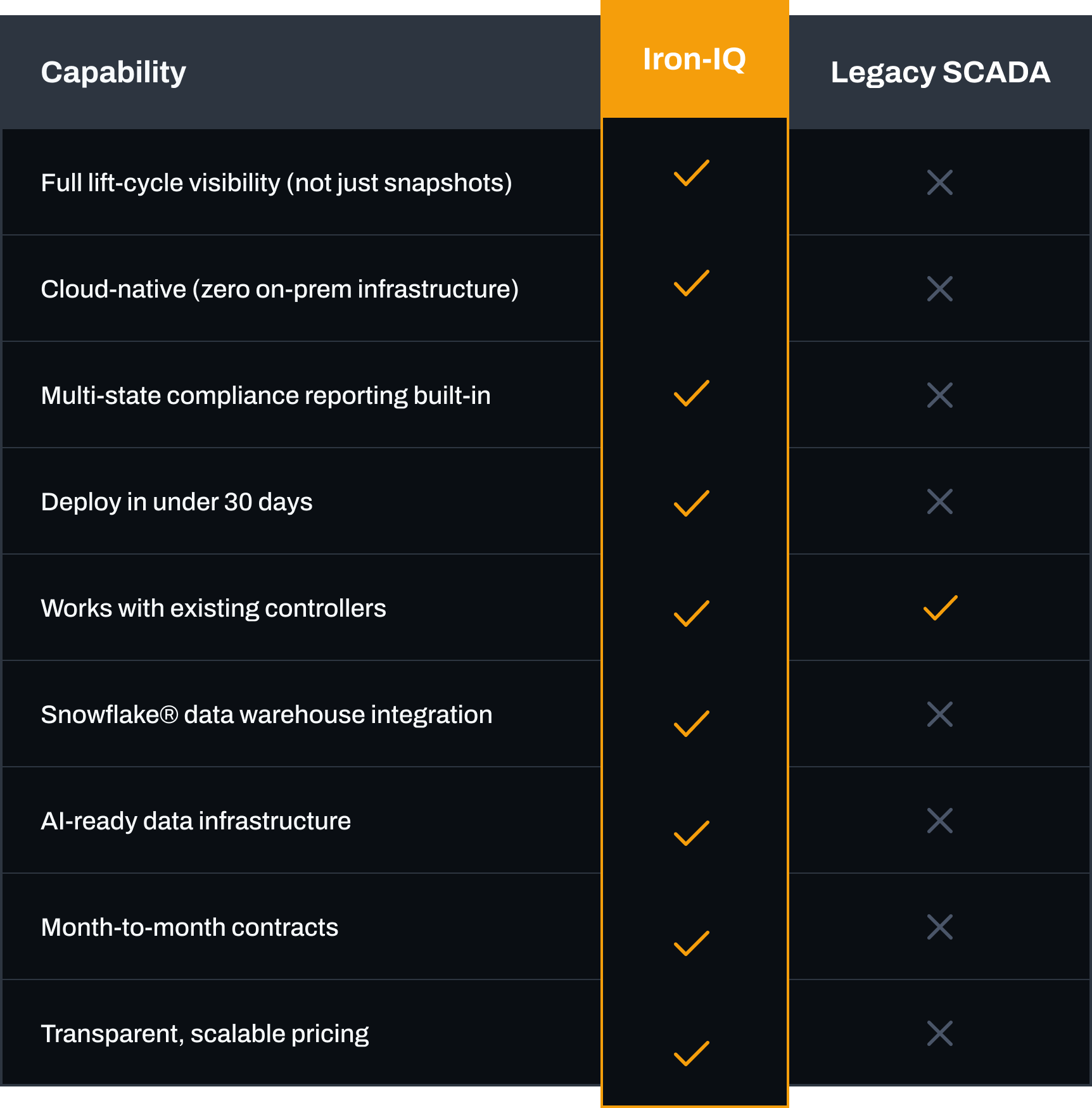

WHY OPERATORS SWITCH

Iron-IQ vs. Legacy SCADA Providers

See why Rocky Mountain operators are moving from traditional SCADA to Iron-IQ's cloud-native platform.

IMPLEMENTATION

Fast Deployment for Rocky Mountain Operators

We understand you can't afford extended downtime or complex IT projects. Get live in weeks, not months.

Week 1:

Rapid Setup

Identify pilot wells, configure controllers, and establish secure cloud connectivity to your Rocky Mountain assets.

Week 2:

Integration

Connect your existing equipment—no hardware replacement required. Maintain full operations during deployment.

Week 3:

Validation

Verify data quality, validate lift cycle capture, and train your team on Galileo analytics dashboards.

Week 4:

Production

Go live with full visibility. Start identifying optimization opportunities and measuring production response.

Demonstrate measurable uplift on your Rocky Mountain wells within 30 days.

Ready to Optimize Your Rocky Mountain Operations?

Start with a Risk-Free Pilot on Your CO, WY, or NM Wells

Select a handful of wells and see the Iron-IQ difference in 30 days.

No long-term commitment required.

Questions? Contact our Rocky Mountain team: sales@iron-iq.com | (877) 664-9355